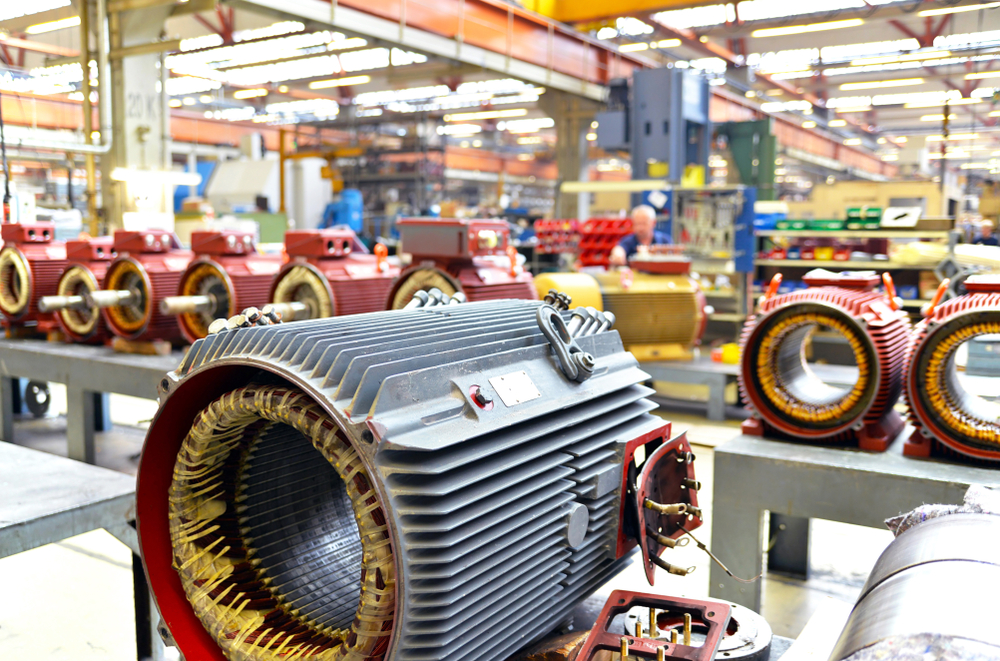

6 Mechanical Problems That Cause Motor Overheating

Motor overheating often gets blamed on electrical problems, but mechanical issues are frequently the real culprit. When motors run hotter than they should, the root cause usually involves something making the motor work harder than designed. Mechanical problems create distinctive heat patterns that point directly to their source, making diagnosis more straightforward than most technicians realize.

If you’ve got a motor running at consistently high temps or continue to see component failures, start your investigation into these six common culprits:

- Misaligned couplings and drive components: Misalignment between the motor and driven load creates friction and binding that shows up as heat. Even slight angular or radial misalignment forces bearings to work harder and creates vibration that wastes energy. The motor compensates by drawing more current, and that extra work generates heat in the windings. Flexible couplings can mask some misalignment, but they’ll wear out faster and still transfer stress back to the motor bearings.

- Bearing wear and contamination: Worn motor bearings increase friction and drag, forcing the motor to work harder to maintain the same speed. Contamination from dust, moisture, or old grease makes this worse by creating additional resistance. As bearing wear progresses, the motor draws more current and generates more heat. The problem compounds because heat accelerates bearing wear, creating a cycle that leads to eventual failure.

- Overloaded or binding mechanical systems: Mechanical binding in the driven system forces the motor to work against resistance that shouldn’t exist. Worn guides, damaged linear bearings, or tight slideways all increase the load on the motor. Sometimes loads gradually increase over time as systems wear or accumulate debris. The motor tries to maintain speed by drawing more current, but that extra current gets converted to heat in the windings.

- Poor ventilation and airflow restrictions: Motors depend on airflow to carry heat away from the housing and windings. Blocked cooling fins, clogged air filters, or accumulated debris restrict this airflow and trap heat. Environmental contamination like oil mist or dust buildup acts as insulation, making heat dissipation even worse. Motors mounted in enclosed spaces or unusual orientations may not get adequate natural convection cooling.

- Incorrect belt tension and drive problems: Over-tensioned belts create excessive side loads on motor bearings, increasing friction and heat generation. Worn or damaged belts cause vibration that wastes energy and creates additional bearing stress. Chain drives with improper tension or worn sprockets have similar effects. Even correctly tensioned belts can cause problems if pulleys are misaligned or if the belt itself is wearing out.

- Ambient temperature and environmental factors: High ambient temperatures reduce the motor’s ability to dissipate heat effectively. Heat from nearby equipment like furnaces, welders, or other motors adds to the thermal load. Enclosed control panels or cabinets can create hot spots that affect motor cooling. Direct sunlight or radiant heat sources can raise motor housing temperature even when the motor isn’t running.

Mechanical problems leave distinct thermal signatures that make diagnosis straightforward once you know the patterns. A motor that runs hot only under load points to mechanical binding or overloading. Heat that builds up gradually over time suggests bearing wear or contamination. Motors that run fine in cool weather but overheat in summer often have ventilation problems. The key is treating heat as a symptom that points to specific mechanical causes, not just an electrical problem to solve with bigger wires or better cooling.